Technical details

The diesel generator ESE 220 TI produced by Endress Group Romania under the Zenessis brand is equipped with IVECO NEF67TM7 engine, Marelli MXB-E 250 SB4 / Strathon ECO 220 KW alternator and ComAp Inteli Lite AMF 25 control system, which ensures the starting of the generator, the control of the parameters, in manual or automatic system. The generator can be supplied with remote control and monitoring as well as other options. Zenessis power generators are guaranteed for 36 months, up to 2000 operating hours.

Standard features

| Diesel engine |

| Command & control panel with measurement & metal control devices, protection class IP54 |

| Static battery charger |

| Dynamic battery charging alternator |

| Controlled thermostat heater for coolant |

| Oversized start battery |

| Emergency stop button |

| Chassis with fuel tank sized for 8hrs of autonomy |

| Vibration dampers |

| Fuel level measuring device |

| Electrical lines protected with tubing & gland |

| Residential silencer |

| Access doors on all 4 sides provided with locks |

| Crane or forklift handling system |

| Flameproof and soundproof insulation |

| Protective pads |

| Metal hinges |

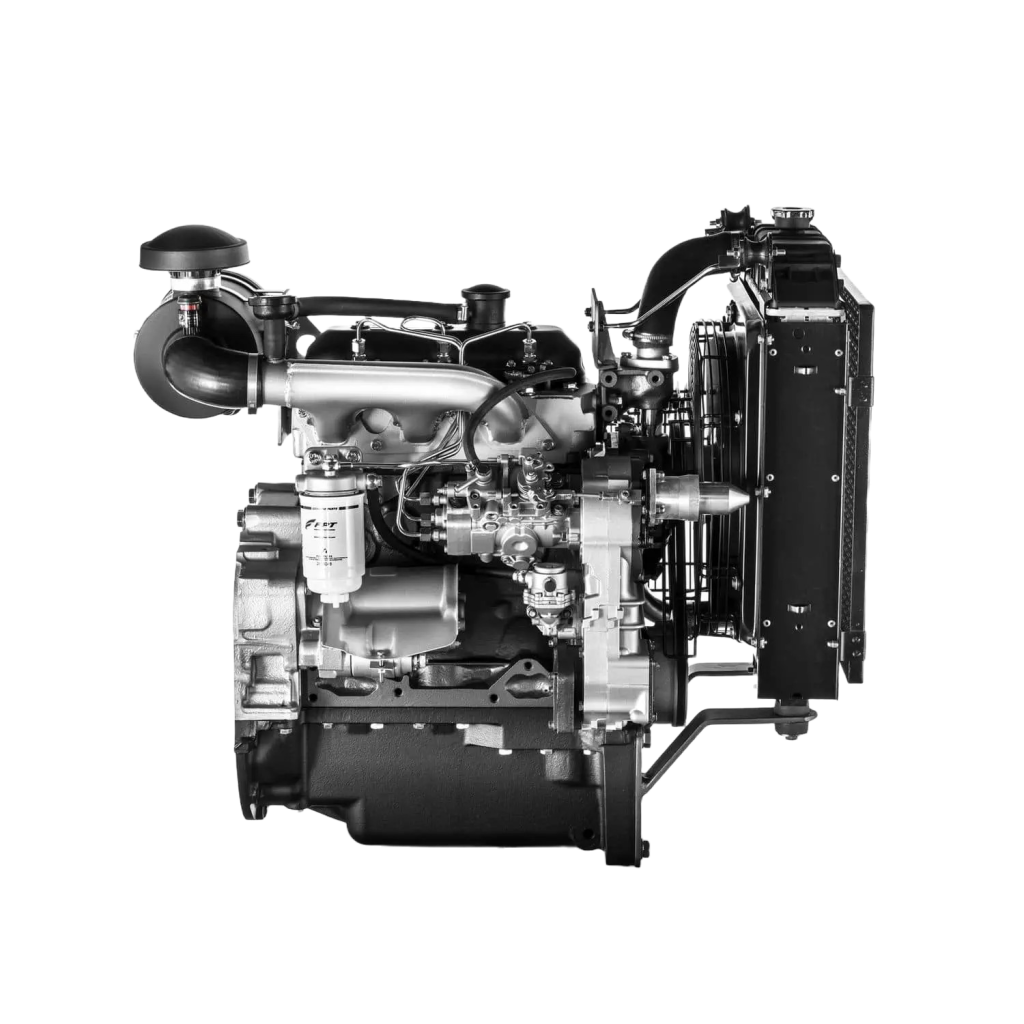

Iveco diesel engine

Engine

| Model | IVECO |

| Model | NEF67TM7 |

| No. of cilinders & arrangement | 6 in linie |

| Cooling system | With liquid (water + 50 % paraffin 11) |

| Induction system | Turbo, secondary air/air coo |

| Injection system | Direct |

| Standby power (kWm) | 195 KWh |

| Speed (rpm) | 1500 rpm |

| Displacement (l) | 6,7 (I) |

| Bore & Stroke (mm) | 104 x 132 mm |

| Compression factor | 17,5 : 1 |

| Regulator | Mechanic |

| Total oil capacity (l) | 17,2 (I) |

| Engine/radiator coolant capacity & hoses | 25,5 (l) |

| Fuel consumption at 100% load (l / h) | 42,1 (l / h) |

Standard features

Alternator Marelli/Strathon

| Model | MXB-E 250 SB4 / ECO 220 KW |

| Frequency (Hz) | 50 Hz |

| Concept | Brushless, 4 poles |

| Power factor | 0.8 |

| Phases | 3 |

| Voltage (V) | 400 / 230 V |

| Excitation system | Electronic |

| Performance | 93% |

| Protection | IP23 |

| Certification test | test EN 10204:2001 |

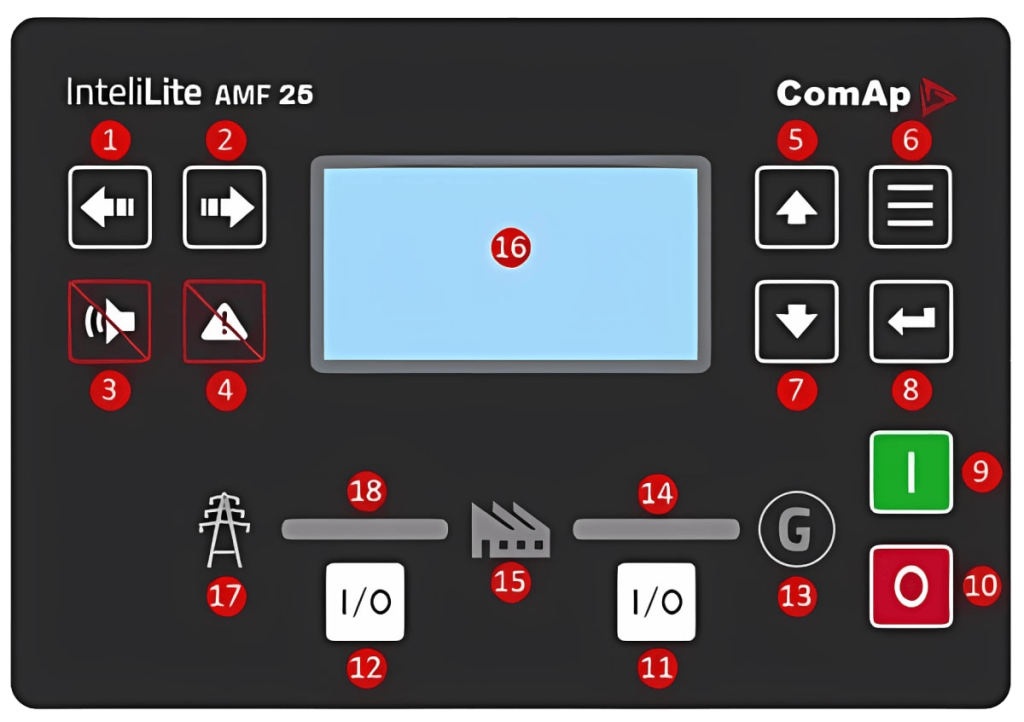

Control panel

Made in metal box, IP54 degree, with lock. The control panel is equipped with the ComAp AMF25 control module, with the possibility of starting and stopping the generator, both in automatic and in electric mode. The control panel monitors the power grid and can command and control the ATS panel (automatic transfer switch).

Control panel standard specifications :

The command and control panel is mounted inside the casing, in a metal box with IP 54, equipped with a viewing glass, equipped with:

| ComAp AMF 25 command module |

| Static battery charger |

| Emergency stop button & circuit breaker fuses control |

| Overcurrent differential protection |

| Protection relays |

Control panel

| 1. Left button |

| 2. Right button |

| 3. Horn Reset button |

| 4. Fault Reset button |

| 5. Up button |

| 6. Page button |

| 7. 7. Down button |

| 8. Enter button |

| 9. Start button |

| 10. Stop button |

| 11. GCB button. Works in MAN and TEST modes only 12. MCB button. Works in MAN and TEST modes only |

| 12. MCB button. 12. MCB button. Works in MAN and TEST modes only |

| 13. Generator status indicator |

| 14. GCB On. Green LEDs are on if GCB is closed and Gen-set is healthy |

| 15. Load |

| 16. Graphic B/W display, 132 x 64 pixeli |

| 17. Mains status indicator |

| 18. MCB On. The green LEDs are “on” when the MCB is closed and the network is within the preset parameters. |

Command module standard specifications:

| Microprocessor control |

| 132 x 64 pixeli LCD display |

| Programming on front panel as well as through PC software |

| Control buttons and soft touch navigation |

| Remote communication via USB or with optional modules via RS232, RS485, Ethernet or SMS |

| Store 180 events with date and time |

| Maintenance programming 3 levels |

| Engine heater control –Optional |

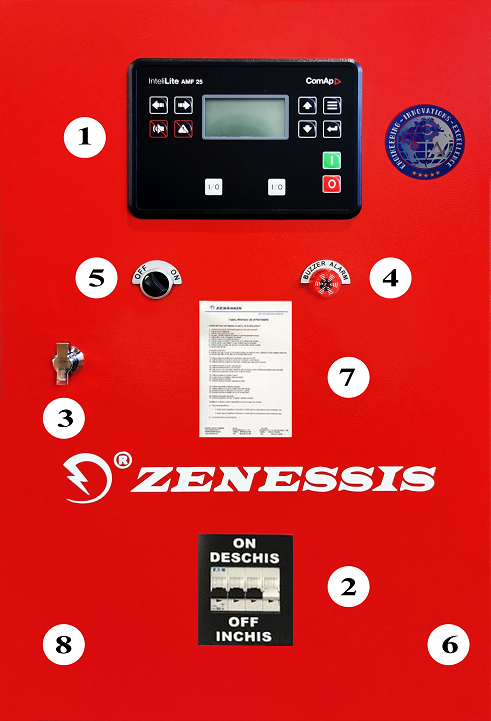

Configuration

Configuration

| 1. ComAp AMF25 command module |

| 2. Circuit Breaker protection |

| 3. Locks |

| 4. Alarm |

| 5. START button ON / OFF |

| 6. Hinges |

| 7. Maintenance schedule |

| 8. Metal box |

Displays:

| Engine – engine speed; oil pressure; coolant temperature; running time; battery voltage; maintenance data. |

| Alternator – voltage (L – L, L – N); current (L1 – L2 – L3); frequency; kW; Pf; kVAr; kWh,kVAh, kVarh; phase sequence. |

| Main network – voltage (L – L, L – N); frequency, mains ready; mains off; generator set ready, generator set disconnected, active power kW, apparent power kVA, reactive power kVA r, power factor, phase sequence. |

| Warning – battery faulty charging, low battery voltage, fail to stop, low fuel level, overload, phase reversing, speed sensor failure. |

| Alarms – low oil pressure, high engine temperature, under / over voltage, under / overfrequency, under / overvoltage, ECU fault -optional. |

| Status displays – missed start, emergency stop, low oil pressure, high engine temperature, under / overspeed, under / overfrequency, under / overvoltage, oil sensor, phase rotation, overload, overcurrent group, phase reversal. |

Static battery charger:

Made with TSD technology, with high efficiency. Protected for short- circuit currents, it can be used as a current source, input voltage 196-264 V, output voltage 27.6 V / 5A or 13.8 V / 5A.

Standards

Electrical safety / EMC, BS EN 60950; BS EN 60950 – 6 – 2 EMC; BS EN 61000 – 6 – 4 EMC.

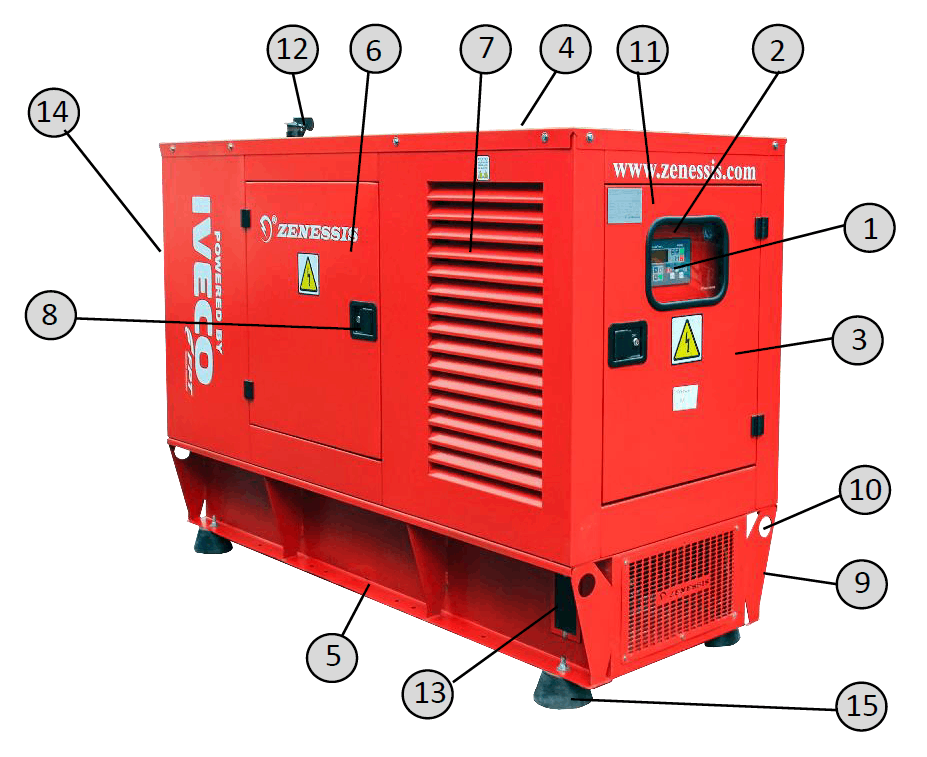

Housing

Made of galvanized steel, painted in electrostatic field, soundproofed. It is modularly designed with in-door access doors on all sides of the generator. The exhaust pan is residential type, mounted inside the casing. The enclosures are designed to optimise cooling of the engine and alternator assembly and can be mounted outdoors, providing weather protection and low noise.

Housing

| 1. Command module |

| 2. View window |

| 3. Access door for control module |

| 4. Points for crane lifting (optional) |

| 5. Spaces for handling with the forklift |

| 6. Usa acces motor si alternato |

| 7. Air intake grills |

| 8. Handles provided with locks |

| 9. Fuel supply bus (optional) |

| 10. „Sleigh chassis” fitted with lifting/pulling holes |

| 11. Emergency button |

| 12. Exhaust Gas Valve |

| 13. Cable access space |

| 14. Hot air outlet grills |

| 15. Protective pads |

Dimensions and weight

Dimensions and weight of open genset

| Sizes (length x width x height) (mm) | 3189 x 1174 x 1620 |

| Weight (kg) | 2010 |

| Fuel tank capacity (liters) | 350 |

Dimensions and weight of the closed genset

| Sizes (length x width x height) (mm) | 3189 x 1174 x 1950 |

| Weight (kg) | 2300 |

| Fuel tank capacity (liters) | 350 |

Optional features

| Electrical panel anti-condensation heating system |

| Fuel / oil heating system |

| Coolant heating circulation pump |

| Oil drain pump |

| Remote monitoring & control system |

| AAR transfer panel with 3/4 poles |

| 3/4 pole differential protection |

| Sokets 400 V/ 230 V |

| Fuel filter with water detection |

| Bypass panel – ENDRESS patented invention – OSIM patent 00010 / 2012 |

| Trailer |

| Start by remote control |

| Groundless protection |

| Interior lightings with switches operated at doors opening |

| Liquid retention tray |

| Liquid leakage detection sensor |

| Motorized ATS, ENDRESS patented invention – OSIM patent 00048 / 2015 |

| Exterior fuel filler cap with lock |

| Pocket system integrated in the chassis for lifting with forklift |

| Fire extinguisher with internal housing support |

| Super soundproof housing |

| Intake air heating spark plug |

| Grounding electrodes |

| Fuel transfer automatic pump |

| Mobile distribution panel with 4 sockets |

| Cable reel |

| Fire detector with automatic shutdown generator set |

| Fire extinguishing system with inert gas |

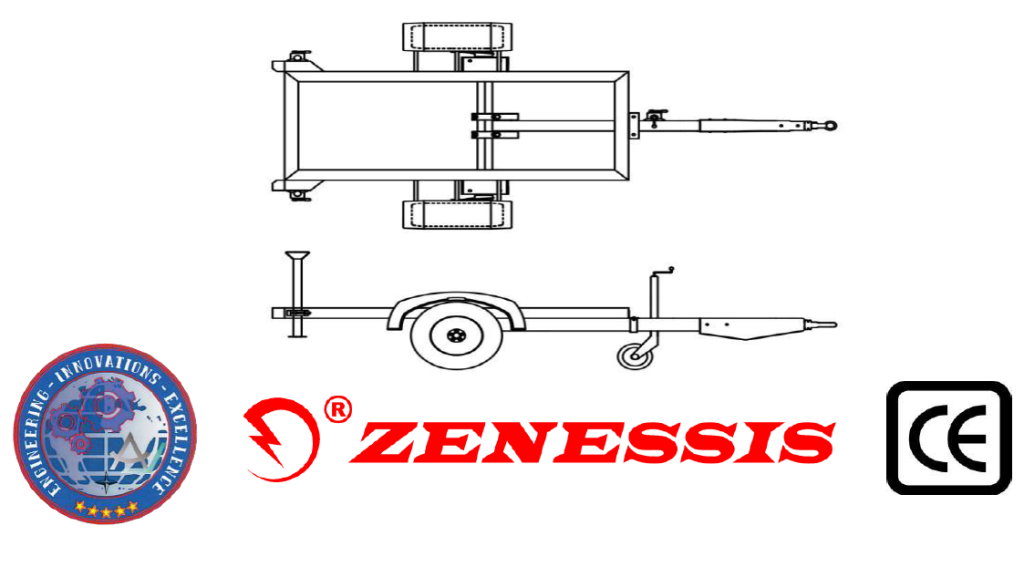

Optional: RAR approved auto trailer

Model: EGR 1350

Endress Group Romania S.R.L. certifications:

ISO 9001 : 2008, ISO 14001 : 2005, ISO 18001 : 2008.

ZENESSIS generator sets are CE compliant, and are tested according to EU noise legislation 2000/14/EC.

Reference ambient conditions: 1000 mbar; 25° C; 30% relative humidity; power according to ISO 3046 / ISO 8528 standards

Prime power (PRP) – ISO 8528

Primary power (PRP) – is the continuous power that a generator is capable of supplying continuously while supplying a variable electrical load when operating for an unlimited number of hours per year under agreed operating conditions, within the maintenance intervals and procedures prescribed by the manufacturer.

Standby power (ESP) – ISO 8528

Standby power (ESP) is the maximum power available at a variable load, under the operating conditions provided, that a generator is able to provide in case of power failure or under test conditions, maintenance intervals and procedures being performed as prescribed by the manufacturer.