Diesel Generators for Hospitals: Ensuring Continuous Power Supply

Why Diesel Generators Are Essential for Hospitals

Diesel generators play a vital role in ensuring an uninterrupted power supply in hospitals, where power outages can endanger patients’ lives.

As an experienced engineer in the generator field, I’ve learned that hospitals have no room for compromise regarding power reliability. Even a brief outage can have serious consequences on the operation of critical medical equipment and emergency procedures.

The Importance of a Stable Power Supply

In a hospital, power supply isn’t just important—it’s critical. Medical teams depend on equipment that monitors and sustains patients’ lives. That’s why diesel generators are essential to prevent outages, especially when the national power grid fails to meet the hospital’s demands.

Benefits of Diesel Generators in Hospitals

- Continuous Reliability: Diesel generators provide a stable and dependable backup source, essential for ensuring uninterrupted operation of critical equipment—even during outages.

- Risk Prevention: In a medical setting, where every minute counts, a backup diesel generator can prevent major risks associated with power failure.

- Support for Critical Operations: Diesel generators ensure continuity for life-saving equipment in emergency situations, from ventilators to patient monitors.

A Real Example of Importance in Hospitals

Într-un proiect recent la un spital din Brașov, am avut ocazia să văd cât de important este un sistem de rezervă bine pus la punct.

When a powerful storm disrupted the local power grid, the diesel generator instantly took over, maintaining power to critical equipment and preventing interruptions in intensive care and surgical units.

How Diesel Generators Ensure Power Continuity

Diesel generators are the primary solution for backup power in hospitals, designed to provide uninterrupted energy supply even in the toughest conditions.

Dual Power Supply for Maximum Safety

A hospital must have at least two independent power sources: one from the national grid and one as backup. If the main grid fails, the diesel generator automatically takes over, keeping essential equipment operational.

Automation of Diesel Generators

Modern diesel generators are equipped with automatic outage detection systems. If a fault is detected in the main grid, the generator starts automatically. No staff intervention is required, and the process is fast and efficient.

Specific Regulations for Diesel Generators in Hospitals

Hospitals are subject to strict energy supply regulations, especially for backup systems. Diesel generators must meet clear technical standards to ensure patient and staff safety.

Basic Requirements:

- Two independent energy sources: One main (grid) and one backup (usually diesel).

- Protection systems: Generators must include systems that detect faults and automatically shut down the unit to avoid hazards.

Regulations governing installation and operation of diesel generators in hospitals are strict, focusing on safety and performance.

Key Requirements Include:

- Automatic shut-off systems: Continuous monitoring of critical parameters (oil pressure, engine temperature). Exceeding limits triggers an automatic shutdown to prevent damage.

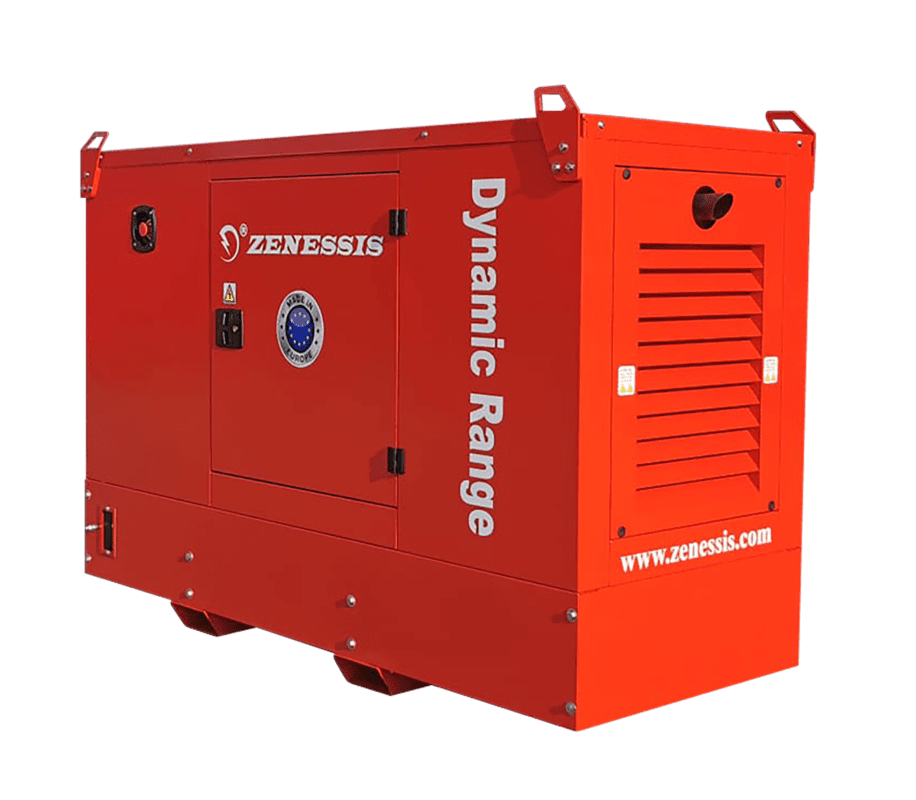

- Noise control: Hospitals are sensitive environments, so generators must include soundproofing systems. For example, in Brașov we selected a model with advanced noise insulation to reduce patient and staff discomfort.

- Fire safety compliance: Generators must be installed in locations compliant with fire safety standards.

Safety Protocols for Failures and Malfunctions

Safety is paramount when operating diesel generators. In case of an incident, generators must automatically shut down to prevent damage or fire risk.

Standard Safety Protocols Include:

- Emergency stop button: Every diesel generator must have a manual emergency stop button accessible to maintenance personnel.

- Monitoring and alarms: If a malfunction occurs, the monitoring system sends alerts to staff for quick intervention—critical for keeping essential systems running.

Installation and Monitoring of Diesel Generators

Technical Requirements for Installation

Installing a diesel generator in a hospital requires strict compliance with technical standards to ensure optimal and safe operation.

Key Requirements Include:

- Installation location: Should allow easy maintenance access and be protected from extreme weather.

- Proper ventilation: Adequate airflow is essential for engine and alternator cooling to prevent overheating.

Monitoring Generator Performance

To ensure proper long-term operation, diesel generators must be constantly monitored. This includes automatic tracking of parameters like oil pressure and engine temperature.

Monitoring Systems Include:

- Alarms and visual signals: Alerts are triggered for issues like low oil pressure or high temperature, and the generator shuts down to prevent further damage.

- Remote control systems: Many hospitals now implement remote monitoring systems, allowing staff to check generator performance off-site, saving time and resources.

Maintenance and Periodic Checks for Diesel Generators

Importance of Regular Maintenance

Regular maintenance is essential for reliable, efficient operation over the long term.

Each diesel generator needs scheduled inspections to avoid critical failures. Based on my experience, I’ve worked closely with technical teams to implement maintenance programs aligned with manufacturer standards.

Essential Checks Include:

- Oil and coolant levels: These should be checked regularly and replaced as needed to prevent engine wear.

- Air and fuel filters: Must be cleaned and replaced periodically to ensure optimal performance.

Critical Technical Aspects for Reliable Hospital Energy Systems

Uninterrupted and Reliable Electric Power

The reliability of a hospital’s energy system heavily depends on diesel generators. A stable, continuous system is essential for operating life-sustaining medical equipment that can’t afford even a brief power loss.

Key Requirements for Reliable Systems:

- Two independent energy sources

- Redundancy: Electrical systems should be designed with backup layers to avoid any interruption.

Medical Fluid Supply and Efficient Thermal Systems

Besides electricity, hospitals also rely on systems for medical fluids (oxygen, compressed air, etc.) and efficient thermal systems (heating, hot water). Diesel generators can support these in emergencies.

Key Considerations:

- Fluid supply backup: Generators must ensure continued fluid delivery during critical situations.

- Heating systems: Controlled indoor temperature is essential for patient safety, and diesel generators can support these systems as well.

Integrated Systems and Energy Management

Implementing an integrated energy management system is essential for long-term efficiency. It helps monitor energy use and optimize resources, leading to significant savings.

Essential Systems Include:

- Monitoring systems: Quickly identify faults and enable prompt intervention.

- Energy automation: Reduces waste and operational costs.

Financial Integration of Diesel Generators

Initial and Operating Costs

Diesel generators are a major investment for hospital infrastructure. In addition to the purchase price, ongoing fuel and maintenance costs must be considered.

Key Cost Components:

- Initial equipment acquisition

- Regular maintenance

- Fuel expenses

Funding Sources for Generators

Hospitals typically finance diesel generators through external loans or public funding sources.

Conclusion & Recommendations

The Importance of Diesel Generators in Hospitals

Diesel generators are essential to keeping critical hospital operations running. They protect vital equipment and ensure continuous energy supply—even during outages. They play a key role in safeguarding patient health and preventing energy-related risks.

Recommendations for Integrating Diesel Generators

- Choose high-quality equipment that meets CE standards

- Ensure professional installation and maintenance

- Continuously monitor performance through automated systems

- Plan for long-term operational and maintenance costs