Standard features

| 2 independent welding positions – 400A each |

| High frequency digital control of welding current and voltage |

| Specific welding programs for cellulose electrodes |

| Double welding scale (50%/ 100%) |

| Auxiliary power available during welding |

| Digital ammeter and voltmeter with presets |

| Engine protection |

| Emergency stop button |

| In accordance with European Commission directives |

| Model | ESE 2 x 400 PS |

| Engine | Perkins 1103A-33TG1 (1500 rpm) |

| Aternator | Three-phase, asynchronous, brushless |

| Fuel | Diesel |

| Current range, continuous | 2×10 ÷ 400 A (bar-TIG) 2×16 ÷ 36 V (flux-cored MIG) |

| Duty cycle | 2×400 A – 35% | 2×360 A – 60% | 2×330 A – 100% |

| Open circuit voltage | 68 V |

| Frequency (Hz) | 50 Hz |

| Three-phase power | 40 kVA / 400 V / 57.8 A |

| Single-phase power | 20 kVA / 230 V / 87 A |

| Single-phase power | 5 kVA / 48 V / 104 A |

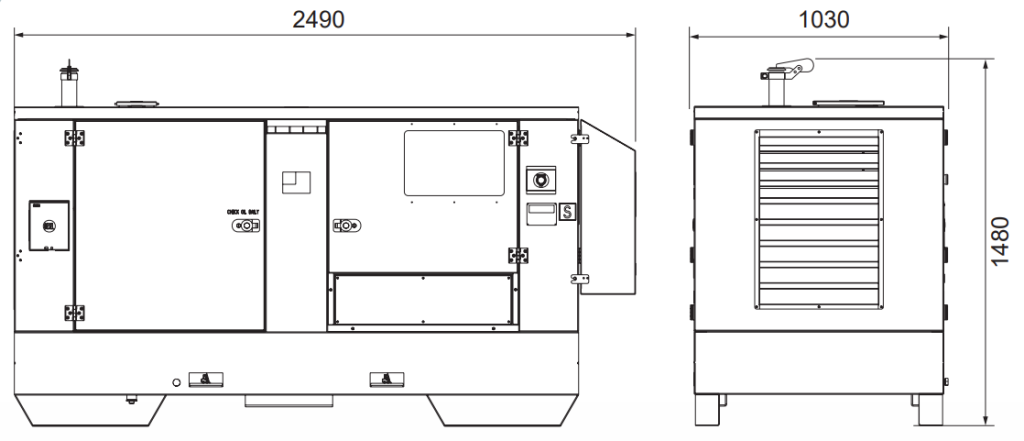

| Dry weight | 1350 |

| Tank capacity | 102 |

| Fuel consumption (welding 60%) | 6.7 l/h |

| Sound pressure LpA | 64 dB(A) @ 7m |

| Prize | 2x400V 32A 3P+N+E CEE, 1x230V 32A 2P+E CEE, 2x230V 16A 2P+E CEE, 2x48V 32A 2P+E CEE, 2 DINSE 200 A sockets for 48V |

Accessories

| Site trailer |

| Car trailer with RAR card |

| Welding cables 20m+15m, 50mm² |

| Remote control cable with 90° connector (20m cable) |

| Remote control cable with 90° connector for version with changed polarity (20m cable) |

| Remote control extension (30m cable) |

| Remote control cable extension (30m cable) |

| Plowing kit |

| Mig-mag wire feeder |

| Welding kit |

| Tank lid with key |

| Heater |

| Main battery switch |

| Water temperature and oil pressure gauges |

| Oil drain pump |

| Izometer |

| Drum with spark protection |

| VRD – Voltage Regulating Device |

| Polarity change |