The Importance of Generator Synchronization in Critical Applications

What Generator Synchronization Means and Why It Matters

Power outages, even brief ones, can cause massive data loss, shutdown of vital equipment, or the complete interruption of complex industrial processes. That’s why organizations operating in sensitive environments — hospitals, data centers, 24/7 factories, telecom systems, or transportation infrastructure — invest in power solutions that offer maximum redundancy and reliability.

One such essential solution is generator synchronization. This technology allows two or more power sources to operate simultaneously, in a balanced and safe manner, sharing the energy load of a facility.

Synchronization isn’t just about starting multiple generators in parallel. It’s about perfectly aligning their frequency, voltage, and phase to ensure smooth transitions, accurate load distribution, and absolute continuity of power supply.

How Synchronization Works: A Simple Explanation

For two generators to work together without causing fluctuations or damage to the electrical system, they must meet these conditions simultaneously:

- Identical frequency (e.g., 50 Hz)

- Identical voltage (e.g., 400V)

- Synchronized phase (i.e., voltage peaks occur at the same time)

These conditions are monitored and adjusted by automatic control systems — synchronization panels, digital controllers, and energy management software. Once all parameters align, the system allows the generators to connect to the load or to each other.

What Is a Critical Application?

A critical application is any system where power failure results in:

- Risk to human life or safety

- Loss of essential data

- Irreversible damage to equipment

- Disruption of operational chains with significant losses

Examples include:

- Intensive care units in hospitals

- Data centers and servers

- Communication systems (antennas, central hubs)

- Air and railway traffic control

- 24/7 manufacturing facilities (smelting, chemical, food production)

In such cases, a single generator is no longer enough. A redundant, modular architecture is needed — a system with synchronized generators that instantly compensates for any failure.

5 Key Advantages of Generator Synchronization

1. True Redundancy in Power Supply

The most important benefit of synchronization is uninterrupted power, even if one generator fails.

Synchronized systems work in parallel, so if one unit goes offline (for maintenance or failure), the others immediately take over the full load. This automatic response eliminates the risk of abrupt shutdowns — a must for critical applications.

2. Smart Load Distribution

Synchronization allows multiple generators to share the total load efficiently. Rather than running a single unit at full capacity — which can lead to rapid wear and high fuel use — the system distributes the load based on each generator’s capacity and efficiency.

In setups with fluctuating loads, synchronized systems can automatically start or stop generators based on real-time demand, ensuring dynamic, adaptive power management.

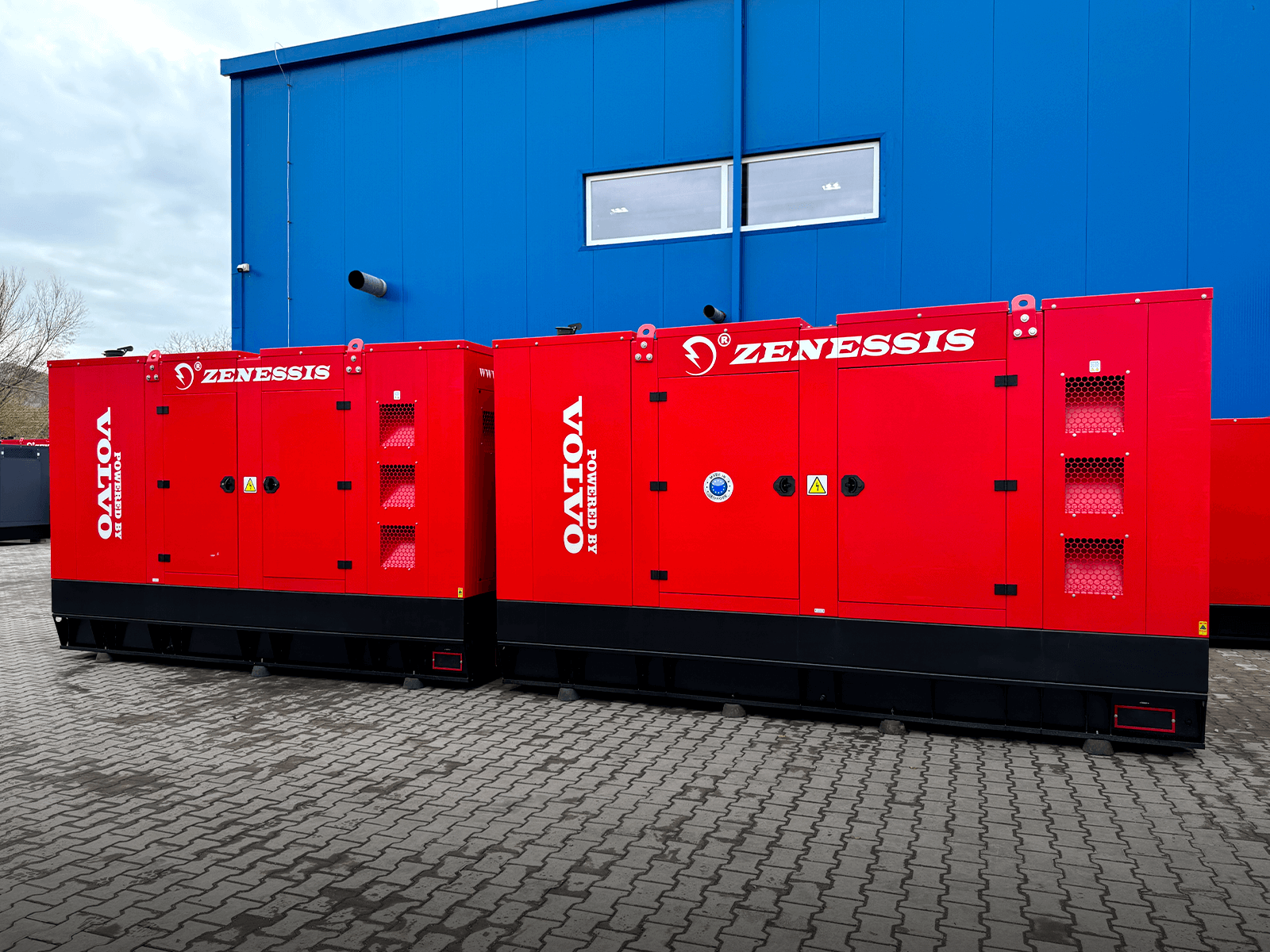

3. Scalability and Modularity

Another major advantage is the easy expansion of the system. If you start with two generators and later need more capacity (e.g., due to a growing data center or factory), you can add more units without redesigning the entire system.

This modular approach offers long-term flexibility. There’s no need to replace everything if power needs double — just add synchronized equipment.

4. Optimized Fuel Use and Cost Savings

In non-synchronized systems, generators might operate outside their optimal efficiency range — for example, under low load, leading to inefficient consumption and problems like soot buildup in exhausts.

Synchronization ensures that only the necessary generators are active, keeping each unit within its ideal performance range.

This reduces fuel use, stabilizes maintenance needs, and lowers operational costs without compromising power reliability.

5. Maintenance Without Full System Shutdown

A challenge with traditional systems is that any technical intervention often requires full power shutdown — unacceptable in critical environments. Synchronized systems solve this: any unit can be taken offline for scheduled maintenance without disrupting the others.

This enables flexible service planning, reduces the risk of accidental failure, and ensures continuous operations.

When Synchronization Is Absolutely Necessary

Generator synchronization isn’t a “nice to have” in critical applications — it’s a technical requirement wherever even a few seconds of power loss can lead to irreversible, costly damage.

There are industries where power must never go out, regardless of external conditions or technical issues. In such cases, synchronization between two or more generators ensures the redundancy and energy stability required.

Examples where synchronization is essential:

- Hospitals and clinics — especially ICUs, operating rooms, laboratories

- Centre de date – unde o întrerupere de câteva secunde poate duce la coruperea fișierelor și pierderea informațiilor

- Continuous manufacturing — chemical processing, food production, metallurgy

- Communication and transport infrastructure — telecom hubs, airports, railways

- Multi-zone critical buildings — administrative or military facilities with independent power zones

In these scenarios, a single generator becomes a single point of failure. If it fails, everything stops. Synchronization eliminates that vulnerability by distributing load across multiple sources.

Real Benefits of Automatic Synchronization in Critical Applications

- Seamless and unnoticeable switching between sources

- Elimination of voltage or frequency spikes

- Real-time adaptation to load changes

- Zero downtime for sensitive equipment

In conclusion, wherever absolute energy continuity is required, generator synchronization goes from being an “innovation” to a mandatory technical standard.

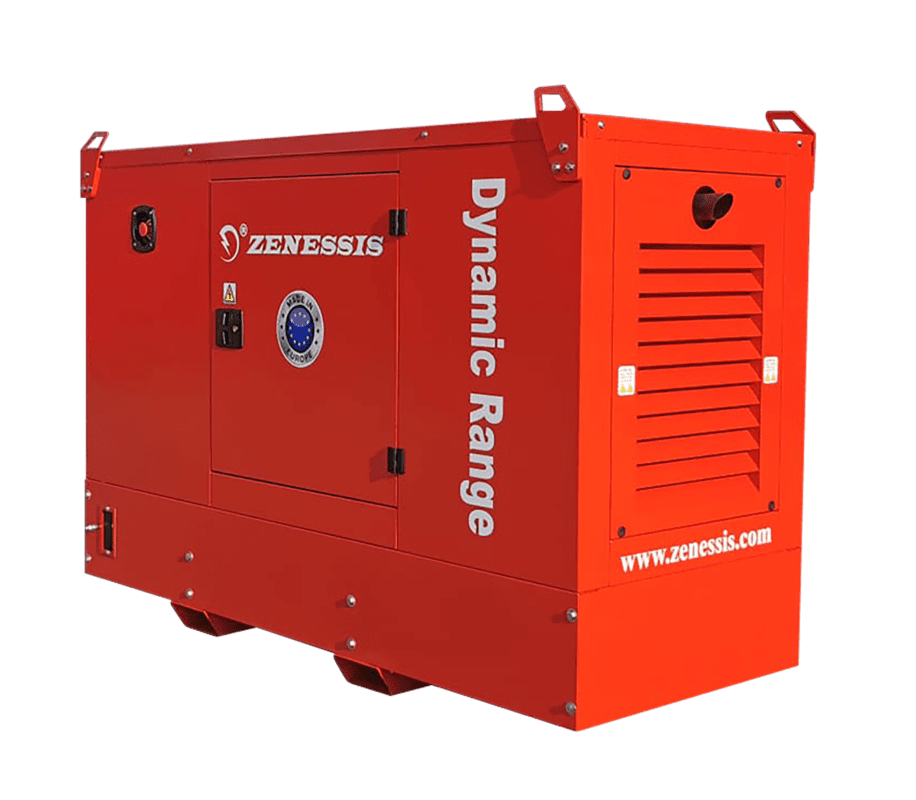

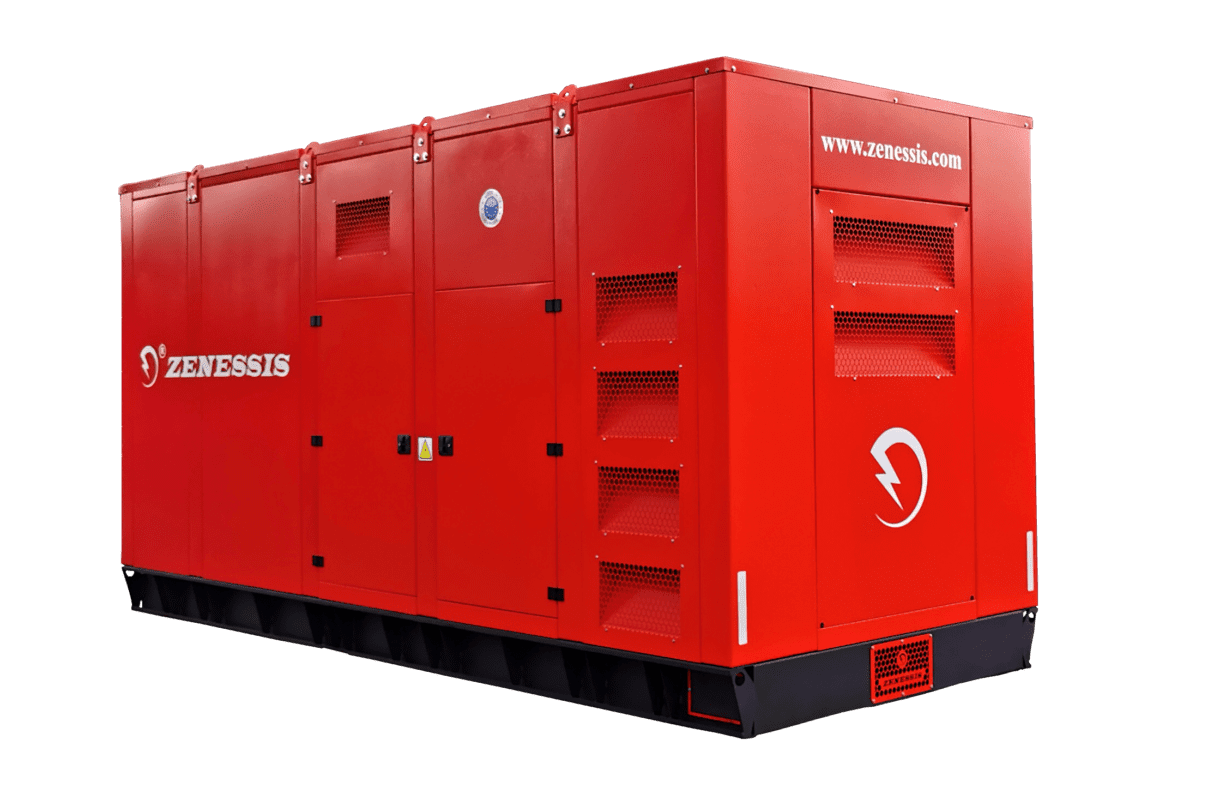

Zenessis Technology: Advanced Synchronization Systems

In critical environments, having multiple generators isn’t enough — you need the technology to manage them safely, efficiently, and intelligently. That’s where Zenessis solutions make the real difference.

Zenessis designs and builds advanced synchronization systems, compatible with a wide range of high-capacity diesel generators, tailored to meet the demands of vital infrastructure.

What Zenessis Synchronization Systems Offer

- Custom Synchronization Panels

Configured for 2, 3, or more generators with automatic connection to the public grid or UPS systems. Equipped with protection against overvoltage, phase imbalance, and frequency loss. - Smart Controllers

Control units constantly monitor each generator’s parameters: voltage, frequency, load, response time. The system dynamically decides which unit to start, how long it runs, and when to shut it down. - Integration with Other Energy Sources

Zenessis solutions support synchronization not only between generators, but also with the national grid or renewable sources (solar panels, wind turbines), enabling hybrid, energy-efficient, and sustainable systems.

Why All These Features Matter

In a critical application, it’s not enough for a system to work — it must be:

- Predictable – able to anticipate risks

- Fast – able to react instantly

- Safe – introducing no instability into the network

- Easy to maintain – minimal, well-planned interventions

Zenessis doesn’t just provide generators — it delivers energy architectures built for absolute continuity. Synchronization systems are a core part of that vision.

3 Common Mistakes in Non-Synchronized System Design

Even though using “multiple generators” may seem sufficient in theory, without proper synchronization, the risks are high. Many companies try to cut initial costs — and end up paying far more in case of failure, surges, or data loss.

1. Assuming One Generator Is “Enough”

A common mistake is choosing one large generator under the assumption it can handle everything. Without synchronized backup, this unit becomes the only support point — and a single point of failure.

If it breaks down, the entire supply is lost. In critical environments, this risk is unacceptable. A synchronized system allows load balancing and redundancy at all times.

2. Using Incompatible Generators

Another major error is combining different generators without ensuring technical compatibility. Different control units and parameters can lead to:

- Phase imbalance

- Voltage differences between sources

- Unexpected overloads

- Harmful electrical vibrations damaging equipment

Proper synchronization is not just physical connection — it means complete harmonization of operation, with precise frequency and phase adjustments managed by specialized controllers.

3. Neglecting Maintenance in Multi-Generator Systems

Some organizations believe that having multiple generators means they don’t need to maintain each one. This mindset is dangerous: a system with 3–4 unsupervised generators quickly becomes unstable if one doesn’t start when needed or causes fluctuations.

Without central monitoring, regular testing, and coordinated servicing, the system loses efficiency and becomes unpredictable — the exact opposite of what’s needed in a critical application.

Synchronization is not just about technology — it’s about operational discipline. A well-designed but poorly maintained system is as risky as a badly designed one.

Conclusion: Synchronization Is Not a “Bonus” — It’s the Standard in Critical Infrastructure

In environments where every second matters, generator synchronization is no longer optional. It’s a fundamental component of any reliable, safe, and scalable power system. Critical applications — from hospitals and data centers to non-stop production and telecom — require solutions that eliminate any risk of interruption. This is only possible through synchronization.

The benefits go beyond the technical:

- Uninterrupted operational continuity

- Optimized energy use

- Reduced equipment wear

- Safety for technical teams and clients

- Scalability without costly overhauls

A non-synchronized system might work — but it will always be fragile, hard to expand, and nearly impossible to control under real pressure. A synchronized system, however, delivers stability, control, flexibility, and durability.

“Without synchronization, you have generators. With synchronization, you have an intelligent power system.”

For companies and institutions that take their power infrastructure seriously, synchronization is no longer a technological luxury — it’s a safety standard.