The Importance of Soundproofing Diesel Generators

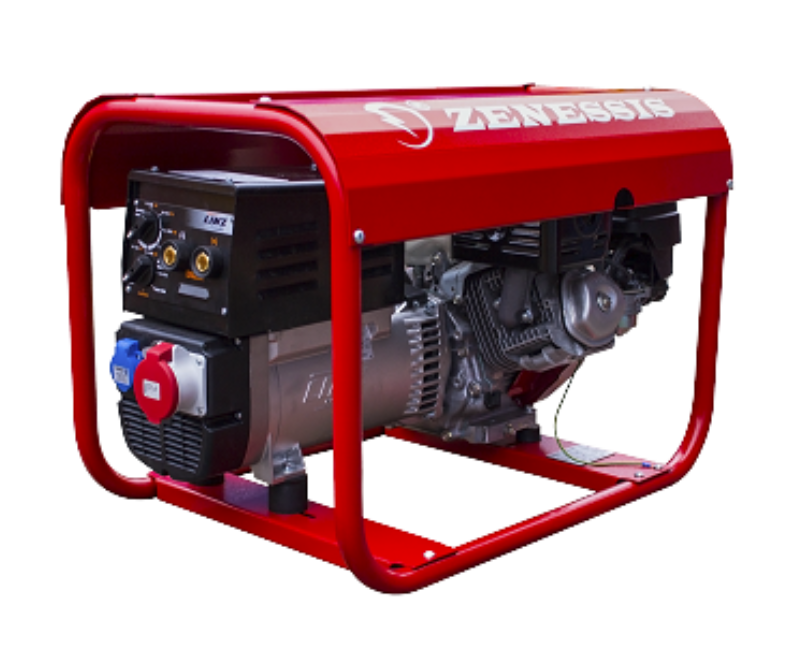

Diesel generators are essential for providing backup power, whether in industrial, commercial, or residential applications. They offer an efficient and reliable solution when the power supply is interrupted. However, one of the major challenges of using diesel generators is the high level of noise they produce during operation. In many cases, the noise can create significant discomfort, affecting the quality of the surrounding environment, whether it’s a workspace or a residential area. The solution lies in the proper soundproofing of these generators, an essential measure for both auditory comfort and maintaining equipment performance.

Noise Generated by Diesel Engines

Diesel generators operate on internal combustion engines, which means that the loud sounds they produce primarily come from fuel combustion, internal parts vibrations, and the exhaust gases exiting through the exhaust system. Depending on the size and capacity of the generator, the noise level ranges from 70 to 100 decibels, a noise level comparable to that of heavy traffic or motorcycles.

Methods of Soundproofing Diesel Generators

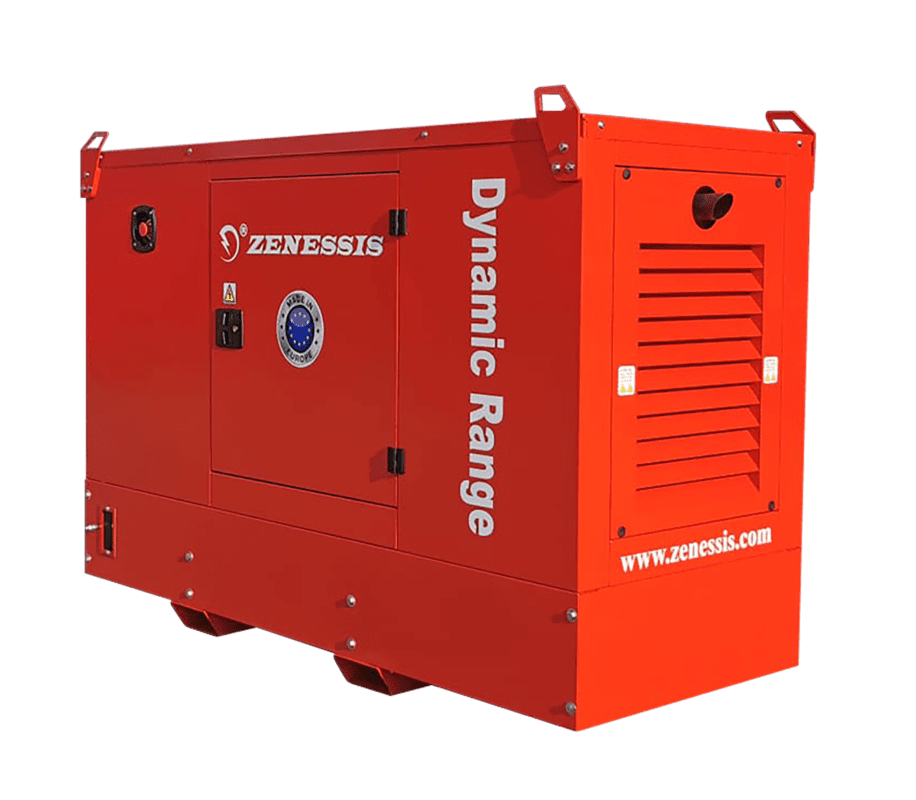

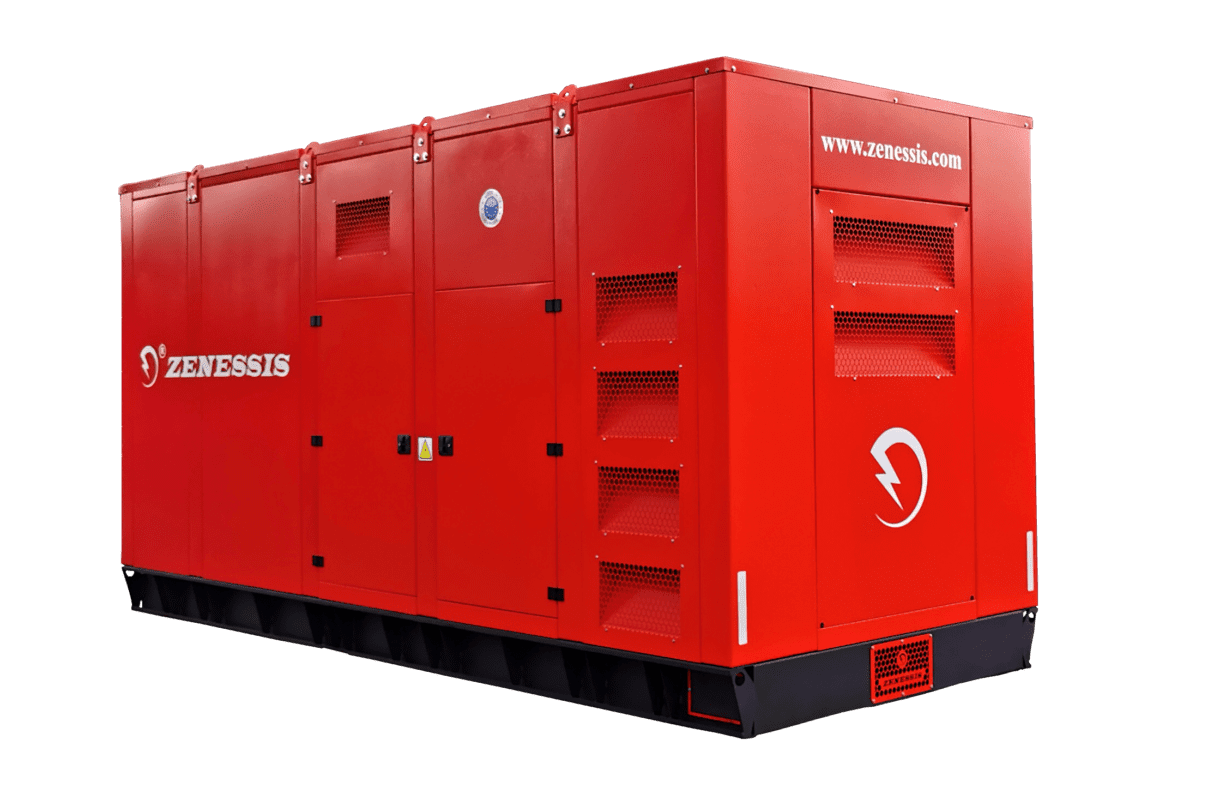

Soundproofing a diesel generator involves implementing technical measures that significantly reduce the noise emitted during operation. The most common method of noise reduction is the use of a soundproof enclosure, which isolates the sounds produced by the engine and prevents their propagation outside. This is especially essential for generators installed in densely populated areas or near workspaces.

The main features of an effective soundproof enclosure include:

- Sound-absorbing materials: The enclosures are made from special materials that reduce the propagation of sound waves, such as acoustic foam or sound-absorbing panels.

- Optimized ventilation design: Ventilation openings and air channels are strategically positioned to allow effective cooling of the generator without compromising acoustic performance.

- Optimized exhaust muffler: The exhaust system plays an important role in noise reduction, and a well-designed muffler can significantly reduce the sounds produced by the exhaust gases.

Advantages of Using a Galvanized Steel Enclosure

Installing a galvanized steel enclosure for diesel generators brings multiple benefits, not only from an acoustic perspective but also regarding the durability and operational safety of the equipment. The main advantages include:

- Noise reduction: The noise emitted by the generator is significantly reduced, improving the working environment and reducing discomfort for those nearby. This is crucial in residential areas or workplaces where noise can distract or affect productivity.

- Generator protection: The galvanized steel enclosure protects the generator from weather conditions and dust particles, ensuring a longer lifespan of the equipment and reducing the need for frequent repairs.

- Improved safety: A well-designed enclosure provides additional protection against accidents caused by moving parts of the generator or other hazardous components, which is important for the safety of operators and equipment.

Soundproofing diesel generators is essential to ensure a balance between functionality and comfort. Noise reduction, protection from environmental factors, and operational safety are just a few of the benefits offered by using efficient soundproofing solutions. These technical measures not only improve working or living conditions but also ensure the consistent performance of the generator in the long term.